In the past, almost everyone used a suction cleaner or pool vaccuum, and we all became accustomed to swimming around the hose, and listening to that ‘tick tick tick’ sound whenever we were near the pool!

However, in the last few years, robotic cleaners have become quite affordable, so are gaining popularity with pool owners. But while it is true that a robotic cleaner can be used in any pool, not every robotic cleaner is suitable for every pool.

If you have an abrasive pool surface such as pebble, you’ll need a cleaner that is strong enough to scrub the surface clean, and durable enough to tolerate any wear against the cleaner skirting.

On the other hand, if you have a soft and flexible surface finish such as vinyl, you need to ensure a robotic cleaner has no sharp edges, and that the tracks and rollers are gentle enough to not cause wear on the pool finish. With all pool finishes, it is also important to ensure there is enough clearance on the underside of the robot to avoid rubbing and scraping against the surface.

So which is better to use? Robotic or suction? It really is a matter of opinion. Suction cleaners have been the norm for many years in Australia, and they generally do a pretty good job, for a very reasonable price. But all pools are different, and no cleaner is perfect (there is usually a corner or step, or some other spot in every pool where the suction cleaner always seems to miss!)

Plus you have to wrestle with the cleaner and hose when you want a quick swim as most pool owners just don’t bother to remove the vacuum from the pool. And when you do finally take the vacuum out, no one ever lays the hose out nice and straight, to minimise any effects of hose kinks on the cleaner’s performance. (Suction cleaners rely on the hose to help control the area they cover and the direction they take).

I’ve personally owned a number of suction cleaners over the years, and a couple of robots, so I thought I’d put together some of my thoughts, to help anyone who is tossing up between a suction cleaner and a robotic cleaner.

Robotic cleaners are designed to be put in the pool once or twice a week for up to 2 hours to roam around the pool in a random pattern and vacuum all the dirt and leaves from the floor and walls. The biggest issue I have with robots is the cleaning! That’s right – you need to clean the cleaner! They need to be cleaned every time they do a full pool clean.

I liked my suction cleaner’s handling of the dirt and leaves, it just sends it all to the pool filtration system. I found my sand filter much easier to clean than the cartridges of the robot – it was just a matter of switching off the pump, turning the valve, then running the pump until the waste water was clear, selecting rinse for a minute and then back to normal filtration. Quite easy really, and only takes about 7 minutes.

The robot takes about 7 minutes each time I clean it – and I have to do this at least every week – whereas I only backwash my sand filter every 4-6 weeks. However, I love the fact that my pool has NO cleaner in the water most of the time and no annoying “tick”, “tick” sound or the surface of the water rippled all the time.

And, when I go for a swim, I jump straight in and don’t have to remove the suction cleaner and store it alongside the pool edge. Now putting the robot in the pool and getting it back out requires a bit of strength, especially getting it out when as you have to wait for the water to drain out before lifting it otherwise it is quite heavy.

Now – the effect of the cleaners on your pool finish. The suction cleaners are often left in the pool all the time as some people choose to swim with them as it is easier. The problem is, for 8 or more hours a day in summer, the suction cleaner is rubbing over the pool surface. If you have an abrasive surface, this will wear the cleaner skirt and some other parts. If you have a soft surface such as PVC, the suction cleaner can rub and wear the surface over time, and if it doesn’t move evenly over all parts of the pool, you may see its common path in form of a wear track, usually around the wall to floor junction.

The concept of a robot being more compatible with all pool surfaces comes from the fact they are only used for a short period of time – BUT you need to make sure you have the correct tracks and rollers for your pool surface finish.

If your pool surface is quite abrasive, then the robot will have less wear on its tracks and rollers as it is only used for relative small amounts of time, but the wearing parts need to be compatible otherwise you will need to replace them quite quickly. If your pool has a soft finish, the robot makes sense as again it is only used for small amount of time, but you need to make sure the areas of contact with your pool finish are compatible so as not to create wear spots.

One of the considerations for your pool before you purchase a robot if you have a softer finish is to ensure the shape of the surface is free of sharp edges, and that there is enough clearance of the underside of the robot to avoid rubbing and scraping these edges, as the hard plastic of the robot body can cause abrasions.

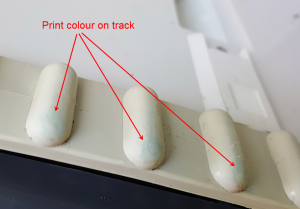

If you ever suspect your robot has caused abrasion to your pool finish, just check the tracks and the underside of the unit – you will likely see some of the pool surface colour on it and maybe some worn plastic parts.

So in my opinion, if you are on a budget or don’t mind swimming with the hose and cleaner, or removing it every time you swim, a suction cleaner will work for you.

If you want the clean look of a pool without a hose and cleaner 99% of the time and happy to rinse off the cartridges after every clean, then a robot will suit you.

Remember, no cleaner is perfect, but they sure beat having to set up the vacuum hose, handle and brush and cleaning the pool manually yourself!